PRODUCT CATEGORIES

Overview

Drum Dryer Introduction

Drum dryer, also named as rotary drum dryer and rotary drying machine, is energy-saving and high efficient drying equipment improved on the basis of original dryer. Drum dryer has reached to the international advanced level through continuous improvement, which can not only deal with high moisture materials with low viscosity, but also the high moisture material with high viscosity.

Drum dryer or rotary drum dryer is suitable for drying metal and nonmetal materials, clay in cement industry, coal slime in coal-mining industry and other materials.

Drum Dryer Features

1. No air leakage phenomenon, completely solve the sealing difficulties and can be installed within two hours.

2. Demand final moisture indicator can be easily controlled according to users' requirements.

3. The discharge temperature is below 50 degrees, and can be directly fed into the cooling shed without cooling.

4. Low energy consumption, low investment, cost saving, energy saving and environmental protection.

Drum Dryer Working Principle

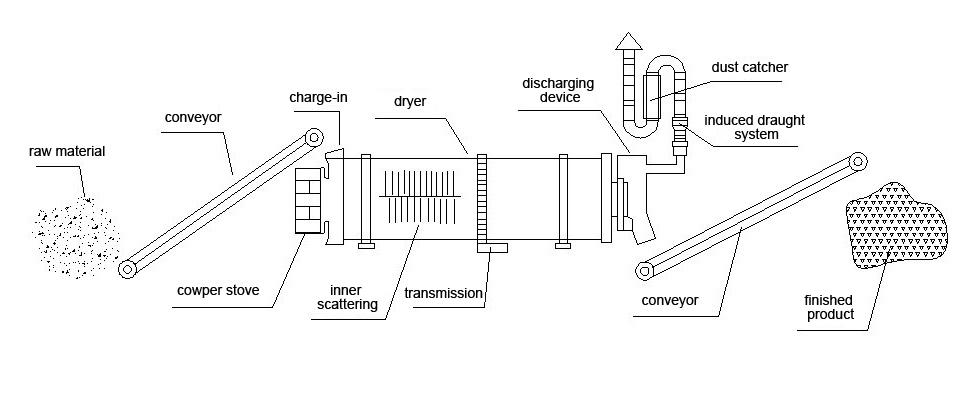

Materials are sent from the higher section of the drum and contact with hot air. With the rotation of cylinder, the material flow down to the lower end with the effect of gravity and discharge after drying. Since the dryer is working under negative pressure conditions, feeding and discharge end use seals to prevent air leakage.

Parameter

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |